01

02

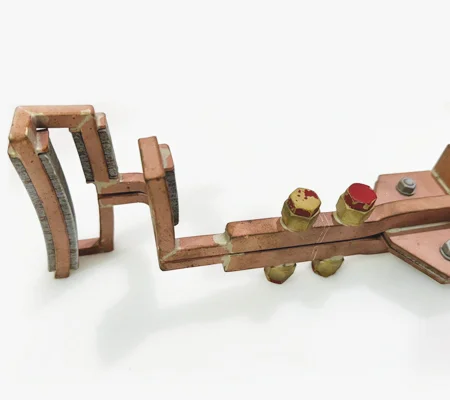

Brazing and Soldering: These inductors are essential in brazing and soldering operations, where precise and localized heating is required to join metal components. The ability to control the heat ensures strong, clean joints without affecting surrounding areas.

03

Forging and Forming: In forging and metal forming applications, induction copper inductors heat metals to their plastic deformation temperature, allowing them to be shaped or molded into desired forms with high precision.

04

Surface Treatment: They are used in surface hardening treatments, such as carburizing or nitriding, to improve wear resistance and fatigue strength by treating only the surface of the metal.