- About Us

- Products

- Services

Industries

01

Automotive

MMF Induction delivers advanced heating solutions for the automotive industry, specializing in hardening, brazing, bonding, and annealing. Our Induction heating systems ensure precise, energy-efficient treatment of components such as gears, rods, sprockets, and suspension parts. This process enhances durability, reduces production time, and supports the high-volume manufacturing of premium automotive components.

02

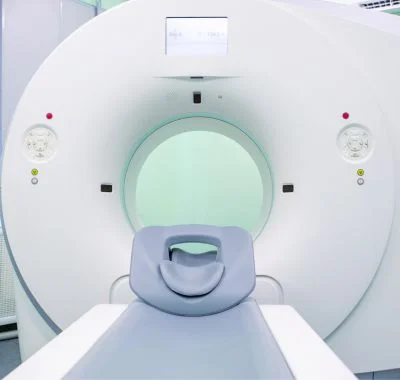

Medical

MMF Induction manufactures advanced induction heating equipment for the medical industry, specializing in copper cathode melting and vacuum sealing of X-ray tubes. Our technology also supports the efficient production of dental equipment and other medical devices, significantly enhancing safety, precision, and reliability across a range of applications.

03

Aerospace

MMF Induction has provided advanced machines to various aerospace industries for critical applications, including part brazing, fuel pipe brazing, and engine component brazing. Our technology excels in bonding and welding high-strength alloys, improving the performance and durability of aircraft components. It supports efficient heat treatment processes, ensuring uniform heating, reducing production time, and maintaining the structural integrity of aerospace parts under the most demanding conditions.

04

Railways

MMF Induction has supplied advanced machines to numerous railway industries, focusing on segmental and single-shot brazing of rotors. Our technology also facilitates efficient track repair and maintenance, enhancing safety and reliability while extending the lifespan of crucial railway components. By meeting these demands, we contribute to the overall performance and durability of the railway infrastructure.

05

Fasteners

MMF Induction has provided advanced machines to the fastener industry for a range of applications, including thread softening, thread creation, and nut hardening, all aimed at enhancing strength and durability. Our induction heating equipment also ensures precise heating and tempering of fasteners to improve performance under stress. Furthermore, it supports efficient production by delivering rapid, uniform heating, reducing cycle times, and ensuring consistent quality of high-strength fasteners.

06

Spring

MMF Induction have supplied machines to the spring industry, induction hardening is used to strengthen and increase the durability of springs. It provides precise, localized heating to harden the surface of the springs while maintaining their core toughness. This process improves the fatigue resistance and overall performance of the springs, ensuring they can withstand repetitive stress and heavy loads. Additionally, induction hardening enhances the longevity and reliability of springs used in various applications.

07

Shrink Fitting

MMF Induction has supplied machines to the shrink fitting industry, induction heating is used to expand components for easy assembly and precise fitting. By heating a part, typically a metal sleeve or ring, it expands to fit over another component. Once cooled, the part contracts, creating a tight, secure fit. This technique is crucial for assembling components with tight tolerances, ensuring accurate alignment, and maintaining structural integrity in high-performance applications.