01

The metal workpiece, typically a pipe, tube, or structural profile, is chosen based on the desired final shape and dimensions.

02

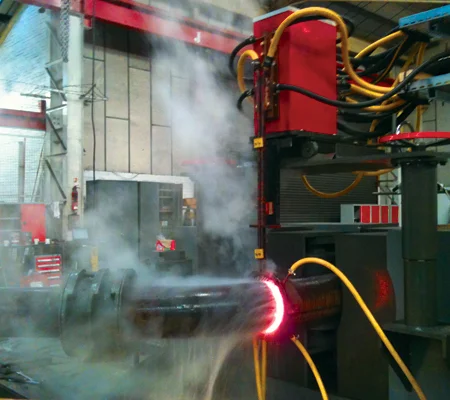

The workpiece is positioned within an induction coil, which is designed to fit the shape and size of the metal.

03

An alternating current flows through the induction coil, generating an electromagnetic field. This field induces eddy currents within the metal, producing localized heat at the specific area where the bend will be made

04

Once the metal reaches the desired temperature and becomes pliable, it is transferred to a bending machine, such as a hydraulic press or roller system.

05

The workpiece is bent to the required angle and radius using the bending mechanism. The precision of this step ensures that the final shape meets the specified design parameters.